How to Fix Electric Motor | Repair Tips for Common Problems

Electric motors are indeed ubiquitous; you can find them in your home, at work, and even in industries. They power everything from household appliances to industrial machines. When these motors fail, it can cause a lot of inconveniences. Do you have an electric motor that is malfunctioning and wondering if it can even be repaired?

The answer is yes; in most situations motors can be repaired, depending on the problem. There are solutions for both starting issues and gradual wear.

This guide will help you understand how to troubleshoot and repair and electric motor that won’t start, three main electrical issues that affect electric motors, and finally, can an electric motor that has burned out be repaired? Let’s start right away.

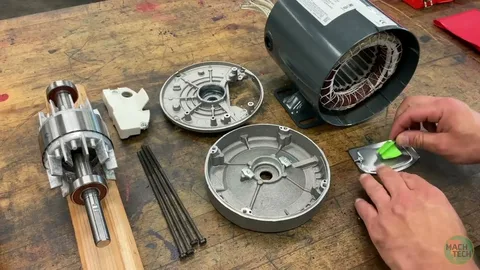

Is It Possible To Repair Electric Motors?

Yes, electric motors are indeed repairable, though it largely depends on what’s wrong with the motor. Many problems associated with electric motors can be resolved if the proper tools, parts, and expertise are available. Still, in some cases, repairs will not be possible, for example, when the core motor components are greatly damaged or burnt to a point where nothing can be done.

These are a few of the issues that can usually be repaired:

Brushes or bearings that have worn out

Spun windings

Damaged connections

Issues with overheating (usually from excess load or lack of oil)

If the bearing motor is reasonably modern and of good quality, it is almost always economical to try a repair. On the other hand, when the problems are too complicated, it’s probably wiser to replace them.

Electric Motors Troubleshooting | Electric Motor Won’t Start

As with other electric motors, the reason why yours might not be startin can be due to many factors. In the below section, we will explain how to troubleshoot to resolve the issue.

1. Inspect the Power Supply

The motor is most likely broken if it does not start running. Check the following on the supply of electricity to the motor. Determine whether or not the motor is being supplied with the needed electrical supply. You need to consider some items first:

You need to make sure the motor is plugged in and that the switch for power is on.

Take a look at the power supply wire for any signs of damage or wear.

Make sure that the circuit breaker is not tripped.

In case the motor is linked to one of the sockets, be sure to check whether the socket is working by checking with a multimeter whether the socket has current.

If the supply of electricity is indeed insufficient, you will have to replace the cable or switch the breaker back on before attempting to start the motor again.

2. Examine the Connections of the Motor

Most of the time a broken motor will have some loose or defective connections. Examine the connections in the motor’s wiring because connections can easily be the problem. This involves the following:

Cables joining the motor and the electrical power source

Sharing loops of grounding or having some control circuitry connected

If you discover loose terminals or wires, then you will make adjustments as needed. Don’t forget to check ecological dirty connections and corrosion as well.

3. Examine the Start Capacitor

Single-phase motors tend to use a start capacitor which provides additional help when starting. If the capacitor is broken, the motor will not start. Checking the capacitor’s operation is as simple as testing it with a multimeter.

In the case of a damaged capacitor, it will have to be fixed. Be certain that the type and voltage ratings for the capacitor are suited for the motor.

4. Inspect the Motor’s Windings

Electric motors make use of copper coils which create magnetic fields. Motors also use electric motors which require a pair of windings. If a pair of windings sustains damage, say by short circuiting, it is highly likely that the motor will not turn on. Follow the outlined instructions to check for winding issues:

Use a multimeter to check continuity across the motor’s coils and winding continuity should be there, or else a short circuit can be detected. If that is the case, then repair or replacement will have to be done with the windings.

Working on a set of windings is quite complicated and might require the attention of an actual professional. Other times, purchasing a new motor can come out as the more viable option in case the winds are severely misplaced.

5. Inspect the Motor Brushes (If Relevant)

In case of a brushed motor, the motor may not start due to the brushes wearing out over time. Inspect the brushes for wear and replace them if required. Additionally, the brush holder should be checked for cleanliness and should not be obstructed by dirt.

6. Check the Bearings

Bearings have a tendency to wear out over time, which results in friction and possible failure of the motor to start or run smoothly. Pay attention to any irritating noise such as grinding or squeaking, as these are indications of bearing failure. Damaged bearings must be replaced.

What Are the Three Most Common Electrical Problems in an Electric Motor?

Electric motors are intricate systems, and knowing their most frequent problems can help you troubleshoot issues in a timely manner. Below are the three most recurring electrical problems related to electric motors:

1. Electrical Overload

When an electric motor draws more current than it was designed to handle, it may pose risk of overheating, damage of windings, or complete motor failure. This condition is called electrical overload. Some of the causes may be:

– Excessive load on the motor\n- Inadequate power supply\n- Poor cooling/ventilation

In order to prevent electrical overload, ensure that the motor is adequately sized for the application, and not overloaded or subject to undue friction.

2. Short Circuits or Grounding Issues

A short circuit or grounding problem occurs whenever the electrical current flows through an undesired and unintended route, like a short between windings or an uncovered wire. This malfunction can cause the motor to fail, or even produce a spark. These are some names causes:

- Worn insulation

- Damaged wires

- Defective or loose connections

Exposed shorts and grounding problems are resolved by inspecting the motor for any visible damage, assessing the wire insulation, and checking continuity of the windings with a multimeter.

3. Failure of Rotor/Stator

The motor’s stator constitutes its underparts as the rotor constitutes the moving parts of the motor. The motor will fail to work correctly if these components are damaged or worn. Some common names causes of stator or rotor failure should be:

- Excessive heat

- Physical damage

- Wear and tear on components

If the rotor or stator is damaged, they may undergo repair or replacement. These issues sometimes may require professional repair service for them to fix.

Can A Burnt-out Electric Motor Be Repaired?

The most critical type of damage a motor can sustain is a burnt-out electric motor, and whether or not it can be repaired will depend on how frequently the motor was used.

What Consequences Will Occur If A Motor Burns Out?

The primary issues that can cause an electric motor to burst are electrical overload, overheating, or a fault within the windings. Continuous accumulation of heat can lead in insulation failure on the motor’s windings, which ultimately leads to short circuits or complete breakdown.

Do You Think This Can Be Repaired?

In most situations, it is possible to repair a burnt out electric motor, but it is highly reliant on the degree the motor has been damaged:

In case the windings are burnt, the insulation is damaged beyond repair, then the motor will need to be rewound which is costly.

If the damage, however, is only to the surface parts like the bearings, or capacitor, these parts can easily be replaced and the motor can become functional.

On the other hand, if the damage is too much and the cost of repairing is set to exceed the cost of a new motor, it is more feasible to get a new motor.

Repairing Your Electric Motor

The problem with an electric motor can be as simple as a loose connection, or it can be complex as well. Whether it’s a motor that doesn’t want to start, an electrical overload, or a motor that is burnt out- all the issues need troubleshooting. Diagnosing the problem is always the first step towards a solution. It is true that electric motors can be repaired, and the most critical issues can be salvaged by using basic tools and a little bit of knowledge.

For queries like “how to fix an electric motor that won’t start,” or “is it possible to repair a burnt out motor,” no worries, with the right analysis and diagnosis, every problem can be fixed.

By following the steps in this guide, you can figure out many of the most common problems like electrical overloads, grounding issues, or bearings and help extend the lifespan, without having to make major repairs.

Post Comment