Asynchronous Electric Motor | Types, Differences, and Applications

Electric motors that operate without a corresponding synchronous motor are what we call electric induction motors or asynchronous electric motors. These types of motors are common in various industries because of their ease in use and effectiveness. What is an asynchronous motor? What sets it apart with a synchronous motor? Does Tesla utilize these types of motors, and what are the classification of 3-phase asynchronous motors? These are some of the questions we will answer diving deeper in the understanding of asynchronous motors in this blog.

What is the Asynchronous Motor?

An electric asynchronous motor or simply an induction motor is an alternating current (AC) electric motor whose rotor revolves at a speed slightly less than the synchronous speed of the magnetic field the stator produces. The gap of the difference in speed gives rise to a phenomenon known as slip, which is required for the operation of the motor.

How Does an Asynchronous Motor Work?

Here is an overview about the operation principle of asynchronous motors:

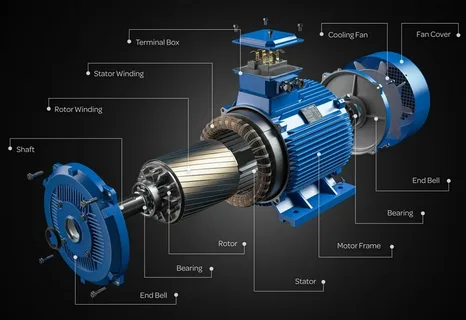

Stator: The stator contains coils which when connected to an alternating current supply, produces a rotating magnetic field.

Rotor: The rotor is placed inside the stator. Its made of conductive bars and these bars are short-circuited by end rings.

Induction: The rotor will generate its own magnetic field because a rotating magnetic field induces currents in the rotor.

Torque Production: The coulomb force created by the interaction of the magnetic field of the stator and the magnetic field of the rotor produces torque making the rotor to turn.

The rotor always turns at less speed than the synchronous speed, hence the word ‘asynchronous.’

What is Asynchronous and Synchronous Motors Difference?

Knowing the differences between synchronous and asynchronous motors is very important for choosing the correct motor for your needs. Here is a summary of the differences:

Synchronous Motors

Speed: The rotor follows the rotational frequency of the stator’s magnetic field, therefore they both move at synchronous speed.

Construction: An external DC source is needed to excite the windings of the rotor for synchronous motors.

Applications: They are used where there is need for precision control of speed like in clocks, robotics, and industrial machinery.

Efficiency: Operating at constant speed (synchronous), they are more efficient but become less efficient when working at variable speeds.

Asynchronous Motors (Induction Motors)

Speed: Shaft speed is less than synchronous speed: Rotor runs at a speed slightly less than synchronous speed (slip) or below synchronous speed.

Construction: Simpler design due to the lack of an external excitation source.

Applications: Common in industrial, commercial, and even domestic application such as pumps, fans and compressors.

Efficiency: Dependable and efficient, particularly in constantly changing speed environments.

Important Difference:

Speed Adjustment: Asynchronous motors are suited for operating in constantly changing speed environments, while synchronous motors allow precise control of speed.

Synchronous motors are more difficult and expensive to produce compared to asynchronous motors which are more affordable and uncomplicated.

Starting Mechanism: Unlike synchronous motors which need a starting aid, asynchronous motors are self-starting.

Does Tesla Use an Asynchronous Motor?

Tesla, a forerunner in the field of electric vehicles, has incorporated both synchronous and asynchronous motors in their vehicles. Let’s look at them more closely.

Asynchronous Motors:

Industry experts believe that Tesla used asynchronous, also known as induction motors, on its first two models, the Roadster and then later the Model S.

Induction motors are best known for their robustness and durability and for having high power outputs.

Synchronous Motors:

Some of the newer models like the Model 3 and Model Y have also had permanent magnet synchronous motors, also referred to as PMSM, integrated into them by Tesla.

PMSM motors are known to be more efficient than others and perform better when going at slower speeds.

The combination of the two types of motors used by Tesla serves as an example of the difference in performance requirements that are necessary for specific applications.

What are the Types of 3 Phase Asynchronous Motors?

3-phase asynchronous motors are the best-known type of induction motor and one of the most widely used in industry and commerce. Here are some types that stand out:

Squirrel Cage Induction Motor

Construction: A rotor that resembles a squirrel cage is fashioned of conductive bars and short-circuited by the end rings.

Pros: Reliability, ease of use, and simple, low maintenance design.

Used in pumps, fans, and conveyors systems, these are found all over the industry.

Wound Rotor Motor (Slip Ring Induction Motors):

Adding external resistance to the rotor windings allows for more external control.

Applications: Used in situations that require high starting torque like cranes and hoists.

Compared to squirrel cage motors, these have more starting torque and speed control.

Double Cage Induction Motors:

Used in harsh industrial conditions, these are extremely durable.

Advantages: These have starting torque and efficiency benefits as well as dual sets of conductive bars in the rotor.

With the combination of having slip ring and squirrel cage motors, these motors are a marvel.

Single Phase Induction Motor:

With these used in household appliances like fans and washing machines, they offer cost efficiency and ease of use.

Simple answer: they’ll work on a single-phase power supply with a split-phase winding.

Simple and effective, these get the job done for small tasks.

Advantages of Asynchronous Motors:

Without the use of slip rings or brushes, motors have lower costs, no need for an external starting mechanism, and less parts that require maintenance.

In need of reliability, these become top picks due to their strength.

In need of long operational life with minimal maintenance, these become best suited.

Demanding harsh conditions, these asynchronous motors prove to have lower initial and maintenance costs making them better than synchronous motors.

High capability needed during variable-speed tasks means being highly efficient and they are, so it’s an easy grab.

Disadvantages of Asynchronous Motors

Asynchronous motors have some disadvantages, such as the following:

Speed Control: Less flexibility in controlling speed compared to synchronous motors.

Starting Torque: Less starting torque in comparison to some other types of motors.

Power Factor: Lower power factor that can require power factor correction in certain applications.

Applications of Asynchronous Motors

Due to their efficiency and dependability, asynchronous motors are widely utilized in various applications, including:

Industrial Machinery: Used in pumps, fans, compressors, and conveyor systems.

Household Appliances: Found in washing machines, refrigerators, and air conditioners.

Commercial Equipment: Asynchronous motors are used in elevators, escalators, and HVAC systems.

Electric Vehicles: Some electric and hybrid cars use asynchronous motors.

Conclusion

Induction, or asynchronous electric motors, are at the foundation of most electrical engineering systems due to induction motors’ simplicity, reliability, and efficiency. Knowing the working principles, types, and applications of the motors helps you with informed choice decisions regarding the right motor for your needs.

Asynchronous motors can best serve as versatile and cost-efficient solutions when designing industrial machinery, household appliances, or electric vehicles. The roles these motors play in providing power to our modern world becomes clearer when differences between synchronous and asynchronous, different types of 3-phase asynchronous motors, their advantages, and disadvantages are explored.

As the asynchronous motors are being continuously improved, their contribution to various industries has and will be critical in terms of marketing innovation and operational efficiency in the years to come.

Post Comment