Brushless DC Electric Motor | Advantages, Downsides, and Comparison with Brushed Motors

These days, everything from drones to electric vehicles makes use of brushless DC electric motors. But what is a brushless dc electric motor? How does it differ from traditional brushed motors? In this blog, we’ll cover the working principles, advantages, downsides, and applications of brushless DC electric motors. Also, we will compare them with brushed motors so that you can know which is better for your requirements.

What is Brushless DC Electric Motor?

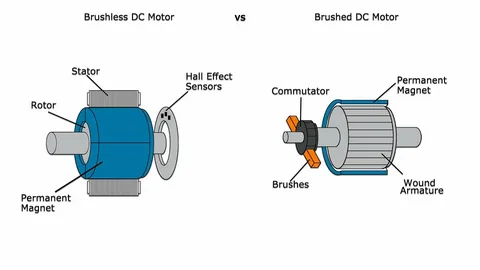

As the name suggests, a brushless DC electric motor is a type of electric motor that has no brushes. Compared to brushed motors that have mechanical brushes that deliver current to the motor’s rotor, brushless DC electric motors use electronic controllers to flow current. This eliminates the need of mechanical commutation, which makes brushless DC electric motors more efficient, durable, and reliable.

What Is the Operation of a Brushless DC Electric Motor?

Just like the brushed motors, brushless DC electric motors function on the principle of electromagnetism. The only difference is how current gets supplied to the rotor. Let us discuss how brushless dc electric motors work step by step:

Stator and Rotor: A brushless DC electric motor comprises a stationary stator containing the windings and a rotating rotor which contains permanent magnets.

Electronic Commutation: Brushes are replaced by an electronic controller that steers the current to the stator windings and a rotating magnetic field is generated that works with the rotor’s permanent magnets.

Rotation: The action of the rotor’s magnets and the stator’s magnetic field results in the generation of torque that will spin the rotor.

Due to the above design, brushless DC electric motors have greater efficiency, smoother operation, and longer lifespans when compared to brushed motors.

What advantages does a brushless electric motor have?

One of the many advantages of brushless DC electric motors is their low maintenance in comparison to brushed motors. In comparison to older models, brushless motors are more popular in today’s world due to:

Lower Energy Consumption: One of the advantages of having no brushes in a brushless motor is the lower consumption rates of electricity. With a higher percentage of energy being converted into mechanized energy, brushless motors can save up to 70% as opposed to older brushed models.

Greater Operational Lifespan: Due to the absence of brushes, the operational life of a brushless motor is considerably longer as there are no factors contributing to wear and tears.

Less Frequent Servicing Needed: Brushed motors need brushes to be cleaned, however DC electric motors do not, thus requiring lesser servicings.

Reduced Noise Emissions: Compared to older brushed motors, brushless motors operate at a much quieter rate, thus being more suited for low noise environments.

Increased precision over speed: Unlike simple motors, brushless DC motors can allow for the easy integration of speed control by an electric controller, thus being suited for complex machinery that operate at variable speeds.

Lightweight and Smaller Size: In comparison to older brushed motors, brushless motors are smaller in size and provide a greater power output, thus proving useful for powering portable hardware like drones.

What Are The Negatives of a Brushless DC Electric Motor?

Even though they come with numerous benefits, disadvantages of brushless DC electric motors also exist. Some challenges associated with brushless DC electric motors include:

More Costly: Compared to other types of motors, brushless DC electric motors tend to be pricier due to the expense associated with the electronic controllers.

Difficulty in Repair: Troubleshooting and repairing the motor system becomes more difficult due to the added electronic controller.

Reliance on Controller: If the electronic controller malfunctions, it becomes useless, and thus relies heavily on electronics.

Less Accessible Replacement Parts: In some instances, replacement parts for brushless DC electric motors are harder to find than for brushed motors.

Regardless of the disadvantages, the motor suffers from high performance functions that require extreme precision and control, the benefits of brushless DC electric motors greatly outweigh the disadvantages.

Brushed or Brushless DC Electric Motor?

Two options are available; brushed and brushless DC motors. Both depend on the characteristics of the specific task. To aid in your decision here is a comprehensive comparison of both brushed and brushless motors:

Brushed DC Motors:

Pros:

Simple design and easy to repair

Lower initial cost

No need for an electronic controller

Cons:

Requires regular maintenance

Shorter lifespan due to brush wear

Lower efficiency due to brush friction

Brushless DC Electric Motors:

Pros:

Low maintenance and quiet operation

Higher efficiency and longer lifespan

Precise speed control and compact design

Cons:

Higher initial cost

More complex system with electronic controllers

When to choose brushed motors:

Brushed motors fit applications with devices designed to accomplish simple tasks and are low power, as lifespan and overall output of the device is not important. Examples include low-powered tools, basic household appliances and small toys

When to choose brushless motors:

Industrial machinery, high-end power tools, drones, electric vehicles and any other device requiring teardown, assembly, advanced output and exact standards.

Standless DC electric motors are used in applications where safety reliability and efficiency are essential including:

Electric Vehicles: These motors are extensively adopted in the designs of electric cars, bikes and scooters due to their high-performance characteristics and small form factors.

Drones and RC Vehicles: Standless DC Electric Motors are used in drones and Remote Controlled vehicles due to their lightweight and the accurate responsiveness to control inputs.

Industrial Machinery: These types of motors are fitted in industrial machinery such as pumps and conveyor belts where reliability and efficiency is crucial.

Household Appliances: Used in many modern appliances such as washing machines, vacuum cleaners and refrigerators, Standless DC Electric Motors increase the operational efficiency and help in achieving near silent operation.

Medical Devices: Used in a number of medical equipment such as surgical tools and ventilators, Standless DC Electric Motors provide precision and reliable performance.

Most Recent Development in Brushless DC Electric Motors

In current times, brushless DC electric motors have already integrated into their system due to their self-improving features. a few of the most recent add-ons include:

Enhanced Algorithms: Integrated into electronics controllers, enhanced algorithms are making the effective integration of brushless DC electric motors into complex systems even more seamless.

Wi-Fi Integration: Brushless DC electric motors are achieving IoT (Internet of Things) integration, allowing remote control.

Sustainability: The exceptional efficiency exhibited from brushless DC electric motors aid the movement towards greener technologies.

Ending

Throughout the years, the use of technology has increased enormously. Since the introduction of motorized devices, brushless DC electric motors have led the way in powering them, standing out for their ease of use and performance with bulky machinery. Even when faced with competition against traditional motors coming from brushed motors, the functionality outweighs the simplicity in almost every case. Despite bearing downsides with their increased price and complexity, brushless motors stand unrivaled in high-performance use cases.

If you are designing an electric vehicle or building a drone, or even if you are just curious about how brushless DC electric motors work, knowing the principles, pros, and cons would help you make sound decisions. There is no doubt that as technology evolves, the innovation of brushless DC electric motors will drive growth in the automotive and healthcare industries.

Studying the working principles, pros, and applications of brushless DC electric motors helps us appreciate the impact they have toward advancing technology. Engineers and inventors have shown us the quiet yet powerful impact of creativity and technology through these motors which we can now control with great precision.

Post Comment