What Does Brushless Motor Electric Mean? Speed, Advantages, and Key Considerations

From drones to electric cars, brushless motor electric technology has become a revolution in modern engineering. What does brushless mean on an electric motor, and why is it so favored? In this blog, we’ll explain how brushless motor electric systems work, their advantages and disadvantages, and answer common queries such as how fast a 2000W brushless motor is, if brushless motors are better, and whether one should get brushed or brushless motors.

What Does Brushless Mean on an Electric Motor?

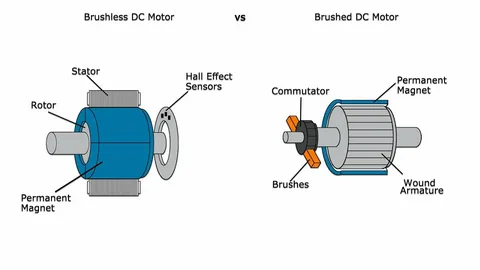

In this case, “brushless” means no brushes are included in the motor’s construction. In traditional brushed motors, mechanical brushes are used to provide current to the rotor, causing wear, friction, and energy loss. A brushless motor electric system, on the other hand, uses an electronic controller to switch the current, which does away with brushes.

How Does a Brushless Motor Electric System Work?

A brushless motor electric system works based on the concept of electromagnetism. As an example of how it works, let me break it down:

Stator and Rotor: The motor contains a stator that is stationary and has windings (the Stator). It also has a rotating rotor that has permanent magnets.

Electronic Commutation: A current flows through stator windings and an external electronic controller rotates the magnetic field B.

Rotation: The resultant combination of the stator’s magnetic field and the rotor’s magnets produces torque which results in rotor spinning motion.

These features allow brushless motor electric systems to operate with more efficiency, durability, and reliability than their brushed motor counterparts.

What are the Advantages of a Brushless Motor Electric System?

As with any technology, brushless motor electric systems also come with their own sets of advantages. Let me list out the most impactful ones:

Greater Efficiency: Since there is no friction from the brushes, brushless motors are better at converting electrical energy into mechanical energy.

Extended Lifespan: For motors that are designed without brushes, wear and tear is reduced and therefore the motor lives longer.

Minimal Maintenance: As there are no brushes that need cleaning or replacing, maintenance is kept at a bare minimum.

Silent Operation: In applications where noise is measured, brushless motors are preferred because they operate silently.

Exact Speed Regulation: The electronic controller, tailored for specific applications, enables precision speed changes for ease in setting variable speed functions.

Lightweight Construction: Compared to brushed motors, brushless motors of similar power are often easier to transport due to being more compact and not having additional weight.

What is the Drawback of a Brushless Motor?

Like all things with pros, a brushless motor electric systems drawback includes:

Increased Price: Due to increased complexity associated with electronic controller systems, brushless motors tend to be more costly to manufacture and sell.

Difficulty: More difficult work due to the added complexity of an electronic controller increases the time required to troubleshoot and repair.

Reliance on Electronics: Without the controller, the motor is not operational if the controller fails.

Fewer Parts Available: Brushless motors are not as widely available so replacement parts could be more challenging to locate compared to brushed motors.

While the disadvantages stand, with most applications falling within the high-performance systems category, the benefits tend to outweigh the negatives.

How Fast Does a 2000W Brushless Motor Spin?

The power rating of a 2000W brushless motor sets its probable top speed at around 10,000 revolutions per minute, though this is contingent on aspects like motor design, load, and the type of application it’s intended for.

For instance, in electric bicycles, a 2000W brushless engine can permit speeds of 45-50 mph (72-80 kilometers per hour) appropriate for high-performance e-bikes. In drones, such a motor can permit rapid acceleration and high-speed maneuvering.

Is a Brushless Electric Motor Better?

It is impossible to answer this question without context. Here is a comparison aimed at aiding this decision.

Brushed Motors

Pros:

Lower initial cost

Simple design and easy to repair

Does not require an electronic controller

Cons:

Lower efficiency because of brush friction

Shorter operational life due to brush wear

Regular maintenance is needed

Brushless Motor Electric Systems

Pros:

Greater operational efficiency and longer lifespan

Low maintenance and quieter while operating

Control over speed and compact construction

Cons:

Higher initial spending

More complicated system with electronic controllers

When to Select Brushed Motors

Brushed motors are appropriate for simple and inexpensive applications where operational efficiency and product longevity do not matter. Smaller toys, basic household items, and low-powered tools are such examples.

When to Select Brushless Motor Electric Systems:

Brushless motors are ideal in situations where performance matters and a combination of sophisticated control, reliable durability, and efficiency is required, such as for drones, electric cars, industrial machines, and even some high-end power tools.

What is my Buying Choice Rather Brushless or Brushed?

Your particular requirements determine whether a brushed or brushless motor is appropriate considering that each has its own advantages and disadvantages. To help you out, here is a brief summary:

Choose Brushed Motors If

Your application is quite simple and requires a low cost solution.

A long lifespan or efficiency are not major considerations.

You want a motor that is easier to maintain and repair.

Choose Brushless Motor Electric Systems If:

There is a need for high efficiency, durability, and precision control.

An increase in expenditure is acceptable in the short term for long lasting value.

Application needs low maintenance and supports quiet operations.

Applications of Brushless Motor Electric Systems

These systems are often integrated into many devices because of their known power efficiency and reliability. Some of the most popular applications are:

Electric Vehicles: Brushless motors have a place in electric cars, scooters, and bikes because of their compactness and high efficiency.

Drones and RC Vehicles: The famous radio controlled drones and their toys make great use of their lightweight and easy control.

Industrial Machinery: They have wide applications in pumps, conveyor belts and other industrial equipment where power efficiency and reliability are required.

Household Appliances: Efficient and quiet operation of modern vacuum cleaners, washing machines, and even refrigerators, is attributed to the use of brushless motors.

Medical devices: The reliability and precision offered by brushless motors makes them ideal in medical equipment, such as surgical tools and ventilators.

Future of brushless electric motor systems

In almost all sectors, brushless motor electric systems are anticipated to have greater innovations and advancements with the upcoming technologies. These include:

Improved Controllers: Modern electronics are making integration of brushless motors into complex frameworks easier, more efficient, and requiring less power due to advanced electronic controllers.

Sustainability: The adoption of sustainable and green technologies is greatly aided by the high efficiency provided by brushless motors, making them highly valued.

Integration With IoT: The integration of brushless motors into IoT (Internet of Things) frameworks allows effortless remote supervision and control mechanisms, making them increasingly popular.

Conclusion

Compared to traditional brushed motors, modern technology is powered more efficiently and with greater longevity and performance using brushless motor electric systems, which offer unrivaled efficiency and durability. Even with the high cost and added complexity, these systems provide unmatched value making them critical with any advanced application.

Whether or not you’re designing an electric vehicle, constructing a drone, or are simply interested in knowing how brushless motors work, knowing their principles, advantages, and issues can assist you in making the right choices. With industry advancements in electric systems using brushless motors, they will certainly be leaders of developmental change from Automotive to Health Care Technologies.

As with any new technology, we can appreciate its impact on the future of engineering and software development by understanding the basic principles, motors’ impact, and their advantages that brushless motors provide with their sharp precision and noiseless functionality.

Post Comment